When it comes to maintaining a comfortable and productive environment in industrial settings, choosing the right air conditioning system is crucial. The best industrial air conditioning system not only ensures optimal temperature control but also contributes to energy efficiency, system longevity, and overall operational costs. In this guide, we’ll explore key factors to consider when selecting an air conditioning system for your industrial facility.

1. Assess Your Cooling Needs

Before diving into options, it’s important to assess your specific cooling requirements. Factors that will affect your decision include:

Facility Size: Larger buildings or warehouses will require systems that can handle high cooling loads and circulate air effectively.

Heat Generation: Consider how much heat your equipment, machinery, or processes generate. For instance, factories with heavy machinery or data centers with high-powered servers may require more robust cooling systems.

Indoor Air Quality: In industrial environments where dust, fumes, or chemicals are present, air conditioning systems that offer effective filtration and air purification should be prioritized.

Understanding these requirements helps narrow down the best options for your facility.

2. Choose the Right Type of Industrial Air Conditioning System

Industrial air conditioning systems come in various designs, each suited for different needs. Here are the main types to consider:

Split Systems

- Best for medium to large spaces

- A cost-effective solution for controlling the temperature in large open areas.

- Ideal for offices, workshops, and assembly areas.

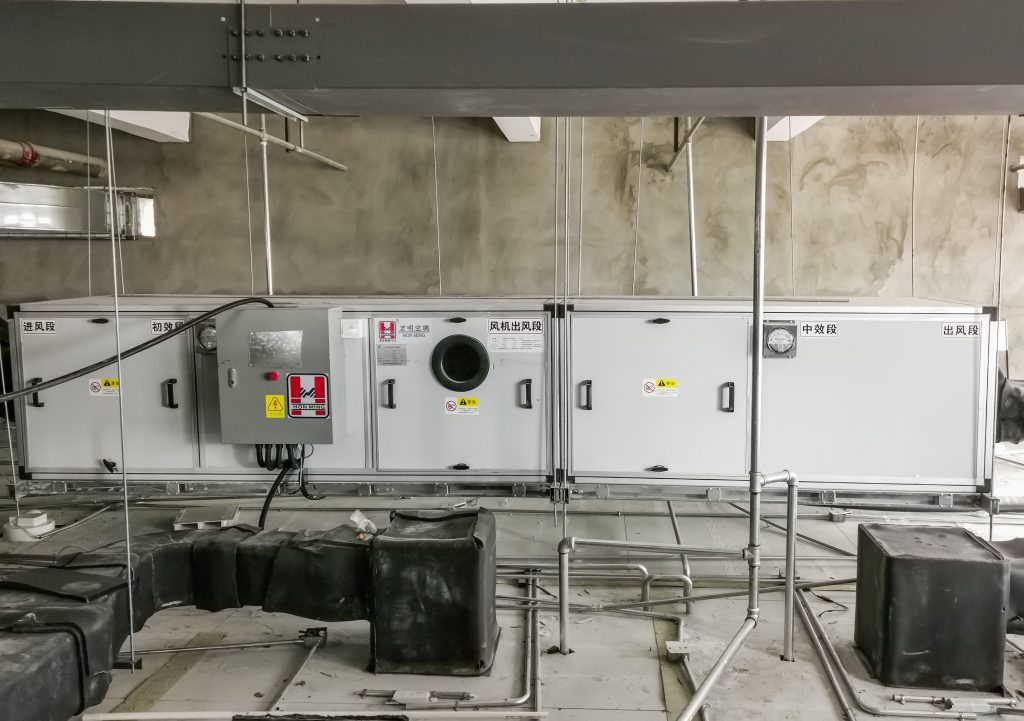

Packaged Air Conditioning Units

- Perfect for larger facilities

- Pre-assembled units that include all components (compressor, condenser, evaporator).

- Suitable for warehouses and large commercial spaces requiring quick installation and high performance.

Chilled Water Systems

- Best for high-load cooling needs in large factories or industrial plants.

- Uses water as a medium for cooling, providing consistent performance and efficiency for larger applications.

- Requires a central chiller plant and cooling towers for optimal functioning.

DX (Direct Expansion) Systems

- Typically used in smaller spaces, ideal for server rooms or small factories.

- Uses refrigerant directly to cool air, providing fast and efficient cooling.

3. Consider Energy Efficiency

Industrial air conditioning systems can be energy-intensive, but selecting an energy-efficient system can reduce operational costs significantly. Here are a few ways to improve energy efficiency:

- Energy Star Ratings: Choose units with high SEER (Seasonal Energy Efficiency Ratio) and EER (Energy Efficiency Ratio) ratings.

- Variable Speed Fans: These systems adjust airflow based on cooling needs, minimizing energy consumption.

- Inverter Technology: Inverter-driven systems provide continuous cooling without the need for frequent on/off cycles, resulting in lower energy bills.

- Smart Thermostats and Controls: Modern systems allow for automated temperature adjustments, reducing energy waste.

4. Look for Reliable and Durable Systems

Since industrial air conditioners work long hours under heavy load, reliability and durability are essential factors in choosing the right system. Consider:

- Brand Reputation: Opt for trusted brands that offer warranties, reliable customer service, and proven track records.

- Maintenance and Serviceability: Choose systems that are easy to maintain and have accessible replacement parts.

- Built for Industrial Use: Ensure the system is designed for industrial-grade environments, where conditions like dust, temperature fluctuations, and humidity can cause wear and tear.

5. Factor in the Cost of Ownership

While the upfront cost is important, the total cost of ownership should also be considered. This includes:

Installation Cost: A professional installation may increase initial costs but ensures optimal performance and efficiency.

Operating Costs: Evaluate the energy consumption and maintenance costs over the lifetime of the system.

Maintenance & Repairs: Plan for regular servicing and upkeep to avoid expensive repairs and system downtime.

Tip: Consider total lifecycle costs instead of just the initial investment when making your decision.

6. Compliance with Regulations

In many industries, air conditioning systems must comply with certain regulations and standards:

- Health & Safety Standards: Systems must ensure safe air quality and temperature regulation for employees.

- Environmental Regulations: Ensure your system is environmentally friendly and meets guidelines for refrigerant use (such as low-GWP refrigerants).

- Local Energy Codes: Ensure the system complies with local or international energy efficiency standards, especially in regulated industries.

7. Conclusion: Making the Right Choice

Choosing the right industrial air conditioning system requires careful consideration of your facility’s needs, budget, and long-term operational goals. Whether you need a split system, chilled water system, or energy-efficient package unit, the best system will enhance comfort, air quality, and operational efficiency in your industrial space.

Ready to choose the best industrial air conditioning system for your businessContact us today for expert guidance and tailored solutions! ?